Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

powder coating Booth

Advanced technology, energy saving, high efficiency.

Powder coating booth is essential for ensuring smooth and efficient powder application. They minimize overspray and ensure a clean, controlled environment for the coating process. There are two main types of powder coating booths:

Fast Color Change Powder Coating Booth With Large Cyclone Recovery System

Designed for quick color changes and efficient powder recovery. The large cyclone system captures overspray and recycles unused powder, reducing waste and improving productivity.

Filter Recovery Powder Coating Booth

Uses high-efficiency filters to capture and recover overspray powder. This type of booth reduces environmental impact by recycling powder and ensuring a cleaner, more sustainable coating process.

Type1: Fast Color Change Powder Coating Booth With Large Cyclone Recovery System

Advanced technology, energy saving, high efficiency.

- Large Cyclone Recovery System

- Quick Color Change Within 10-15 Minutes

- 95%-98% Powder Recovery Efficiency

- No Dust Spillage, Minimal Powder Waste

- Easy To Clean Quickly, Reducing Downtime

- Using Well-Known Brand Components

- Efficient Separation And Recovery Of Powders

- Easy To Maintain And Replace Parts

Features

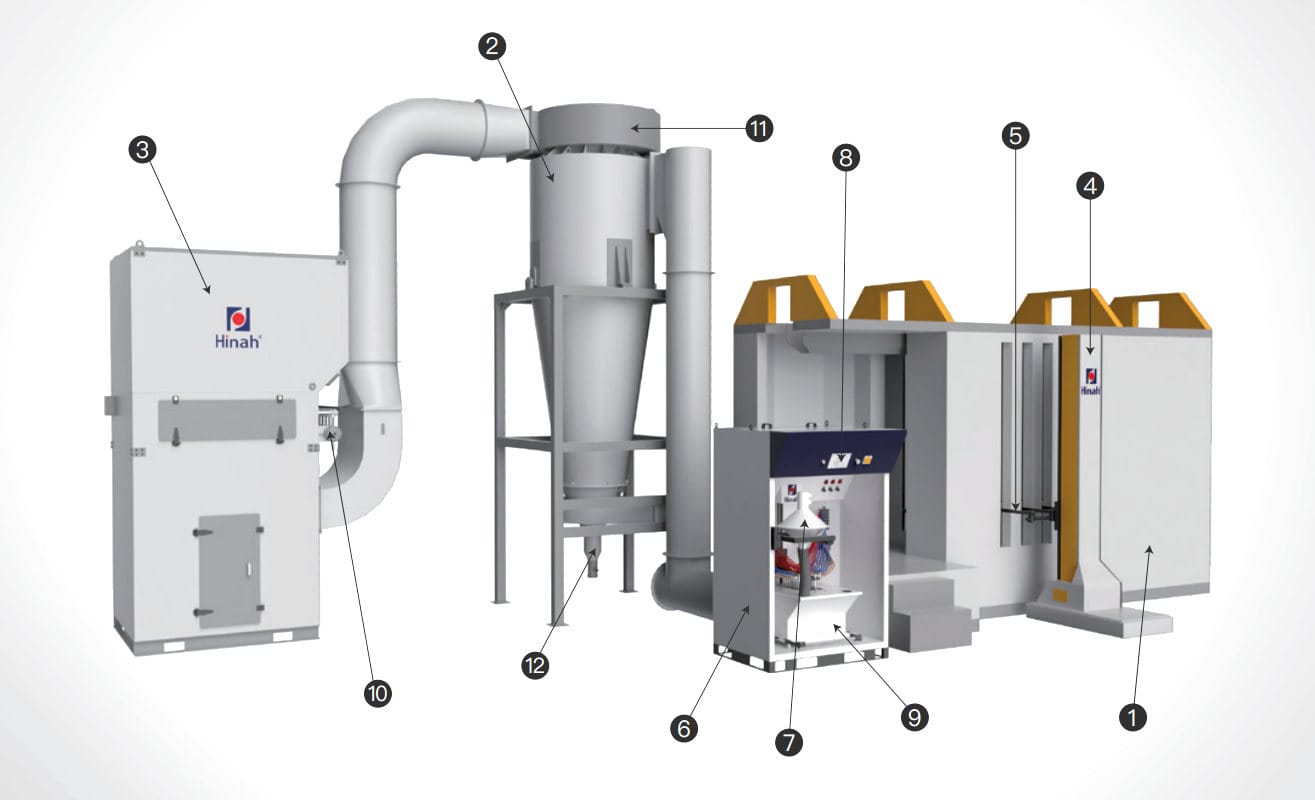

Fast Color Change Powder Coating Booth With Large Cyclone Recovery System

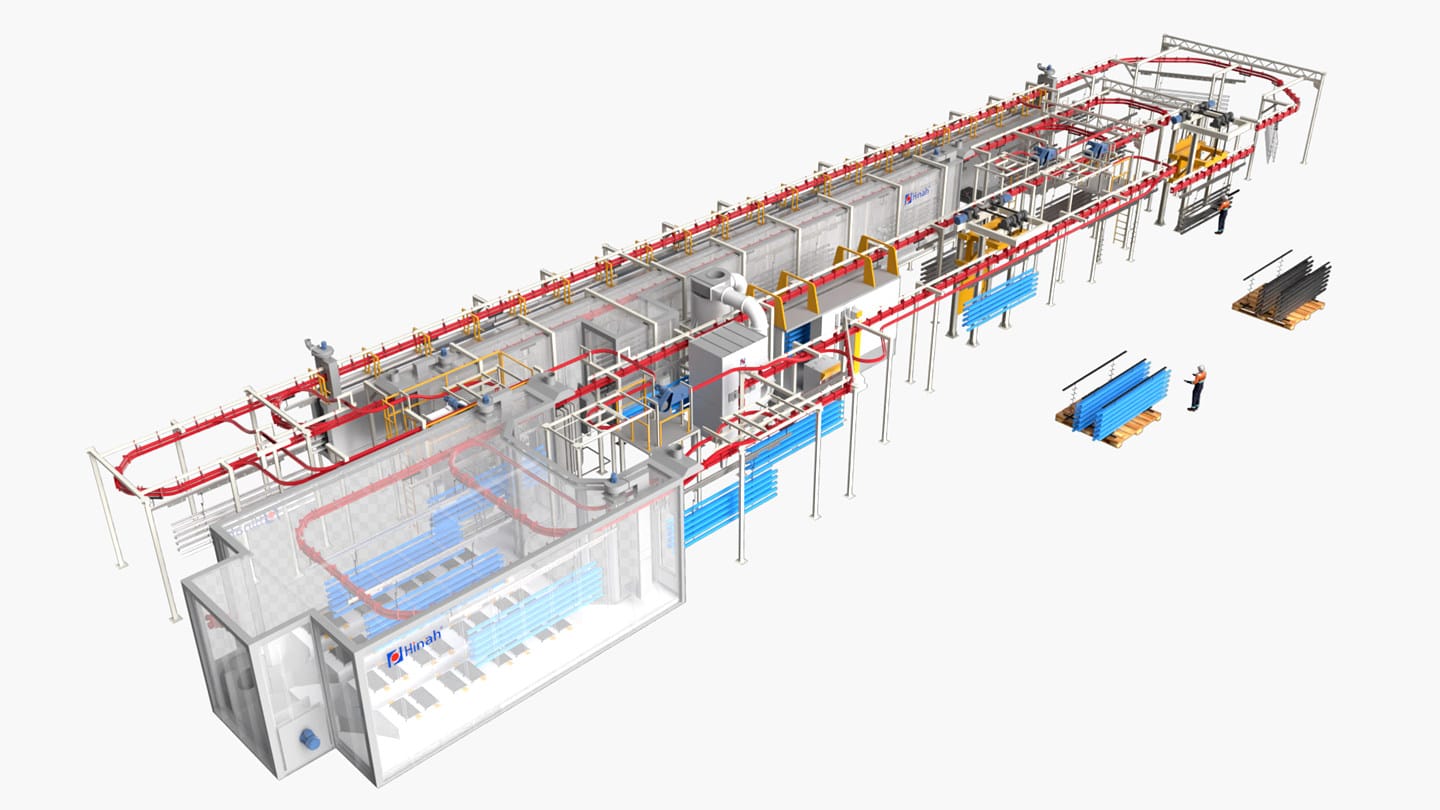

Our powder coating booths are equipped with a Large Cyclone Secondary Recovery Device, which efficiently captures overspray powder and separates it from the airflow. This system ensures high recovery rates(95%-98%) and reduces powder wastage, resulting in cost savings and environmental benefits. And can change color in 10-15 mins. This system utilizes high-efficiency filters to capture overspray powder, ensuring clean air emissions and maintaining a safe working environment as well as cost-effectiveness.

① Powder Coating Booth

② Cyclone System

③ Secondary Filter System

④ Reciprocator

⑤ Coating Gun Rack

⑥ Powder Feeding Center

⑦ Vibrating Sieve

⑧ HMI Touching Screen

⑨ Powder Silo

⑩ Filter Cleaning Device

⑪ Resistance Reducer

⑫ Powder Recovery Pipe

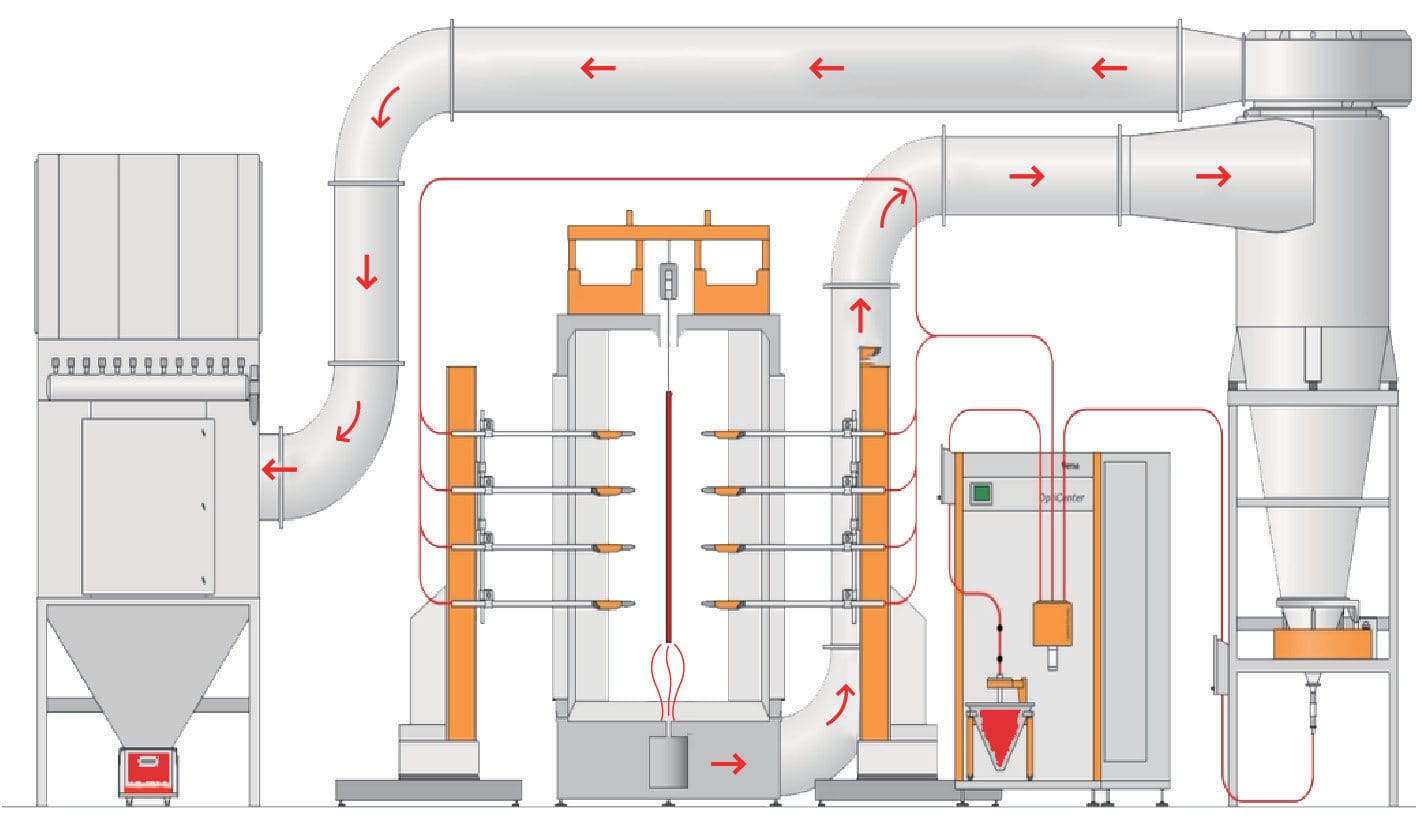

Working principle of large cyclone powder coating booth

● Spraying stage: Powder is sprayed evenly on the surface of the workpiece through the spray gun.

● Powder recovery: Unattached powder is sucked into the large cyclone recovery system by the fan.

● Cyclone separation: The large cyclone recovery system uses centrifugal force to separate powder from the air.

● Powder collection: The separated powder is collected and can be reused to ensure a high recovery rate.

● Air filtration: The filtered clean air is discharged to the outside to keep the working environment clean.

Working principle of powder coating booth

Spraying process: The electrostatic powder coating equipment is in the spraying room. The powder flies to the sprayed workpiece with static electricity under the action of air pressure. 30-40% of the powder is adsorbed on the surface of the workpiece to complete the coverage.

Recycling process: 60-70% of the powder in the air is recovered by the suction cyclone recovery machine. The powder rotates in the cyclone barrel and is separated under the action of centrifugal force. The dust falls into the bottom of the ash hopper and the air is discharged from the middle.

Filter element cleaning: The air in the powder spraying room is crushed by the filter element to form an outward airflow to prevent the powder from overflowing. The accumulation of powder on the surface of the filter element will cause blockage. The pulse cleaning system automatically cleans the powder on the surface of the filter element to ensure that the air duct is unobstructed and maintains the good effect of the recycling system.

Type2: Filter Recovery Powder Coating Booth

Advanced technology, energy saving, high efficiency.

- High-efficiency filtration for maximum powder recovery

- Reduces environmental pollution and airborne powder

- Easy-to-replace filters for minimal maintenance

- Ensures a clean and safe working environment

- High powder recovery rate, minimizing material waste

- Designed for long-term durability and reliability

- Reduces operational costs by recycling powder effectively

- Extend equipment life, strong durability, and reduce maintenance frequency

Features

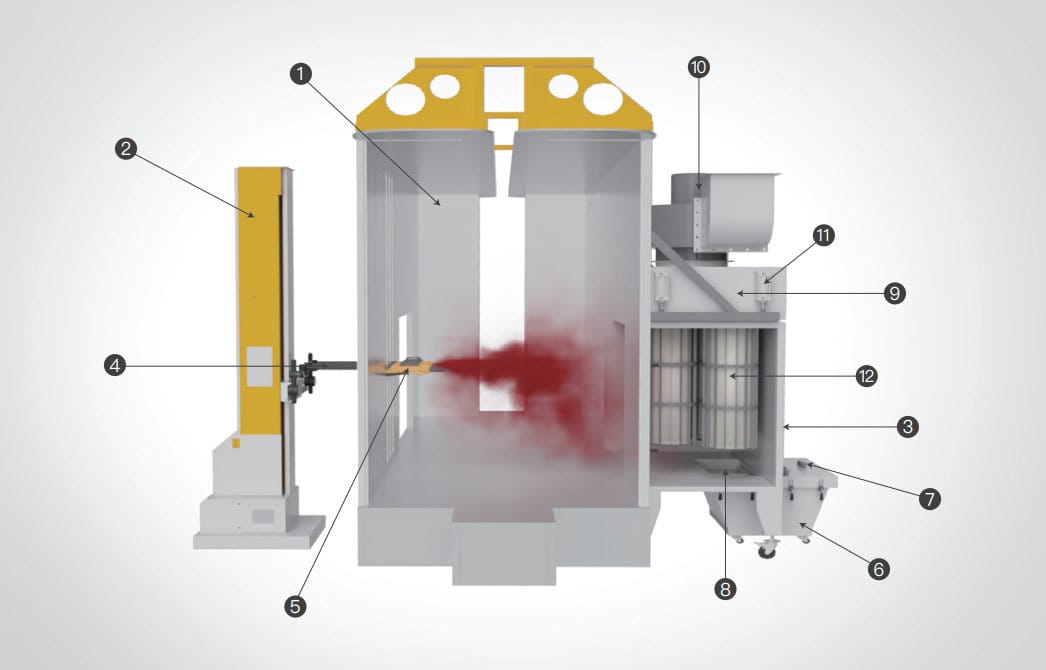

Manual Color Change Powder Coating Booth With Recovery Filter System

In a powder coating booth equipped with a cartridge recovery system, a suction fan sucks the powder particles out of the air and the cartridge filter captures them. Low investment costs are one of the main advantages of the manual color change powder coating booth with a recovery filter system.

Allowing the operator to move freely, making the spraying operation more flexible and able to easily cope with various shapes and sizes of workpieces.

By adopting high-pressure spraying technology, the powder coating can be completely mixed with air to form a uniform powder cloud, thus realizing uniform spraying on the surface of the workpiece.

① Powder Coating Booth

② Reciprocator

③ Recovery Filter Box

④ Coating Gun Rack

⑤ Powder Coating Gun

⑥ Powder Silo

⑦ Powder Feeding Port

⑧ Powder Recovery Door

⑨ Negative Pressure Chamber

⑩ Negative pressure fan

⑪ Quick Release Cylinder

⑫ Filter

Working principle of filter recovery powder coating booth

When operating the powder coating booth, the floating powder that is not adsorbed on the workpiece to be coated is sucked by the exhaust fan together with the indoor air and flows to the filter element opposite the operation port. After being filtered by the filter element made of filter materials such as parchment paper, the powder is trapped in the room, and the air is discharged to the outside through the filter element. In this way, when the filter element is back-blown with compressed air at a fixed time, the powder on the surface of the filter element falls into the collection box at the bottom of the room and can be recycled and reused. The continuous exhaust not only maintains the negative pressure in the room, so the powder cannot overflow, but also ensures that the dust concentration in the room does not exceed the explosion limit.

The advantages of this recovery configuration are compact structure and small footprint. Since there is no need for connecting pipes, maintenance and cleaning are very convenient, and the equipment investment is relatively small.

Working principle of powder coating booth

Spraying process: When operating the powder spraying room, the floating powder that is not adsorbed on the workpiece to be coated is sucked by the exhaust fan together with the indoor air, and flows to the filter element opposite the operation port.

Recycling process: After being filtered by the filter element made of filter materials such as parchment paper, the powder is trapped in the room, and the air is discharged to the outside through the filter element. In this way, when the filter element is back-blown with compressed air at a fixed time, the powder on the surface of the filter element falls into the collection box at the bottom of the room and can be recycled and reused.

Filter element cleaning: The air in the powder spraying room is crushed by the filter element to form an outward airflow to prevent the powder from overflowing. The accumulation of powder on the surface of the filter element will cause blockage. The pulse cleaning system automatically cleans the powder on the surface of the filter element to ensure that the air duct is unobstructed and maintains the good effect of the recycling system.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Contact Us -- Free Design & Order Equipment Calculation

Order Equipment Calculation

In Order To Provide You With The Best Solution, Please Tell Us The Following Information

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.