Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Fully Automatic Liquid Painting Line

The Most Efficient Painting Solution.

We provide our clients with exactly matched designs, reliable equipment, and safe, complete, and efficient production liquid painting systems.

We provide bespoke Liquid Painting Lines designed specifically to address the unique needs and production requirements of each of our customers. Our customized painting lines are meticulously crafted to meet the distinct demands of your industry and the specific characteristics of your products. By doing so, we ensure that you achieve optimal production efficiency, maintain high coating quality, and enjoy significant cost-effectiveness throughout your operations. With our tailored solutions, you can confidently enhance your production processes and achieve outstanding results.

- All Types Of Equipment For Liquid Painting Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 12 Months Warranty And Lifetime Service

Fully automatic liquid paint spraying lines are suitable for a very wide range of applications, whether it is an orbital paint dipping line or a plastic dipping line, and are able to achieve fast spraying. Together with the fully automatic paint spraying robot, it can achieve a higher automation effect, reduce pollution, and lower production costs. The integrated smart control system ensures precise coating thickness and uniform coverage, even for complex geometries or temperature-sensitive substrates.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Project Case

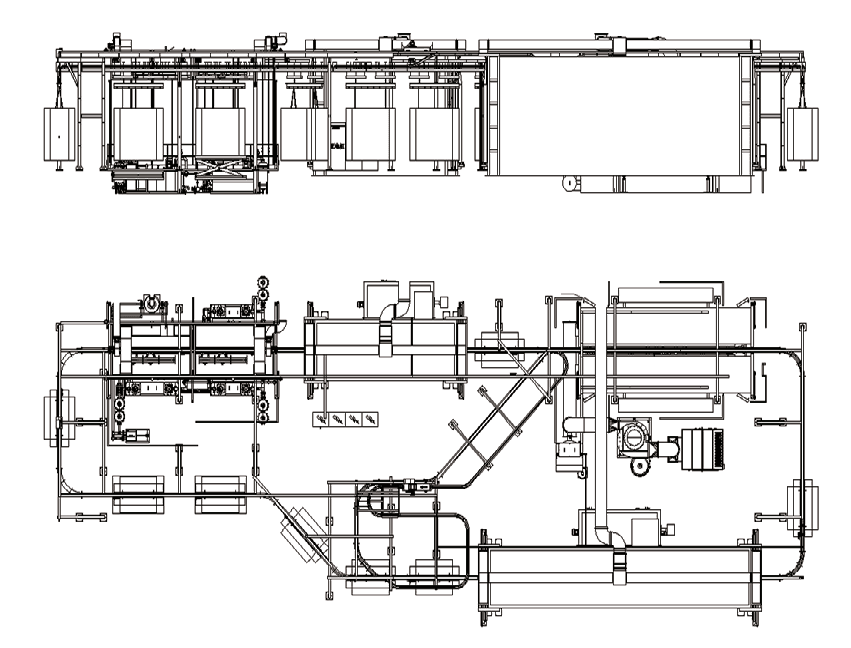

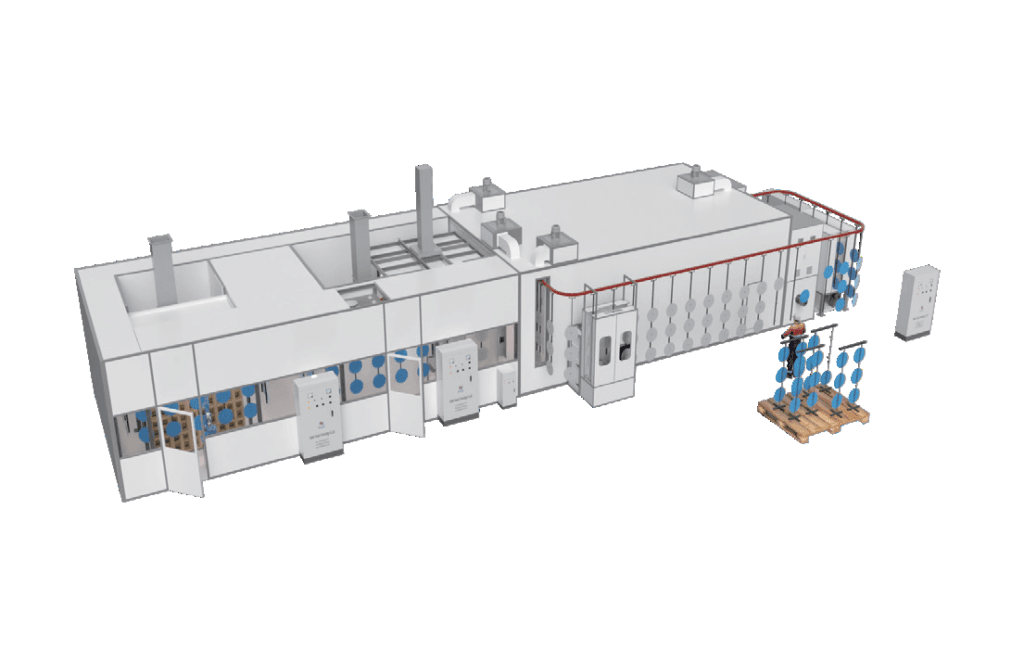

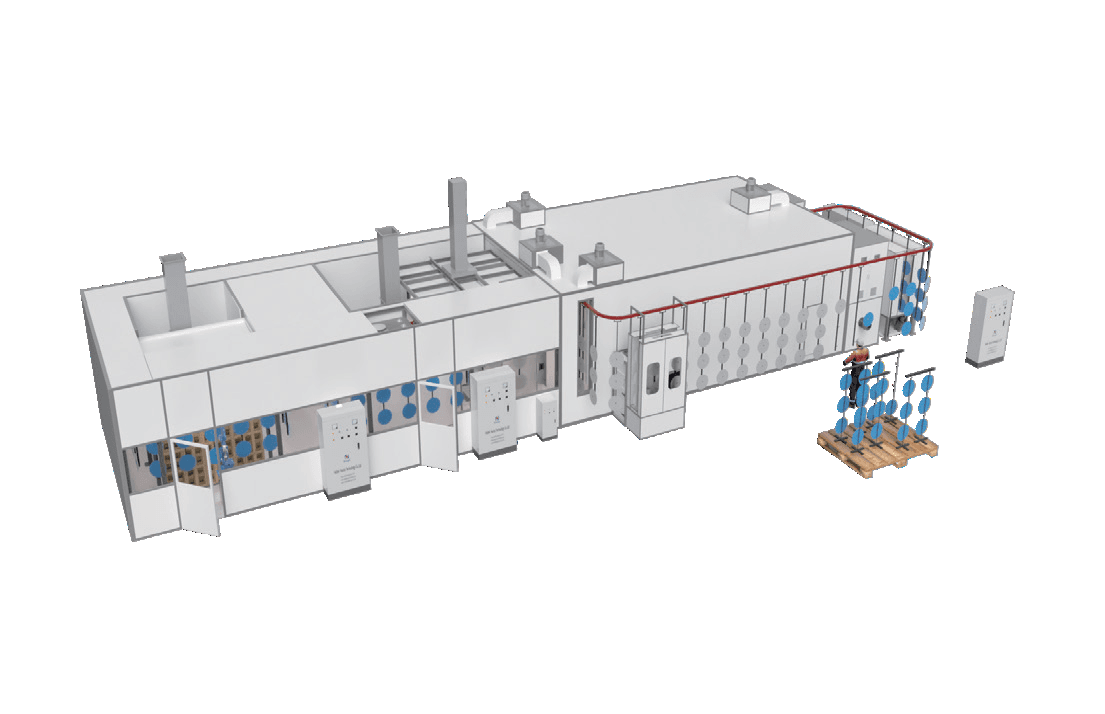

Case 1: Liquid Painting Line

① Workpiece dust removal system

② Drying furnace system

③ Ω spray painting room

④ Robot spraying room

⑤ Flash drying room

⑥ Curing furnace system

⑦ Forced cooling room

⑧ Conveyor chain

Spray Effect: Achieves fast spraying speeds with uniform coating, high efficiency, low energy consumption, and enhanced production output.

Fully Automatic Conveyance: Features an auxiliary automatic shifting device for loading and unloading, accommodating variations in material lengths, and ensuring complete process automation.

Quick Color Change System: Offers a customizable quick color change system tailored to customer needs, significantly reducing gun cleaning time and improving equipment utilization.

Retractable Paint Booth: Designed for large, medium, and small workpieces, these adjustable booths optimize production output with a compact structure and user-friendly operation.

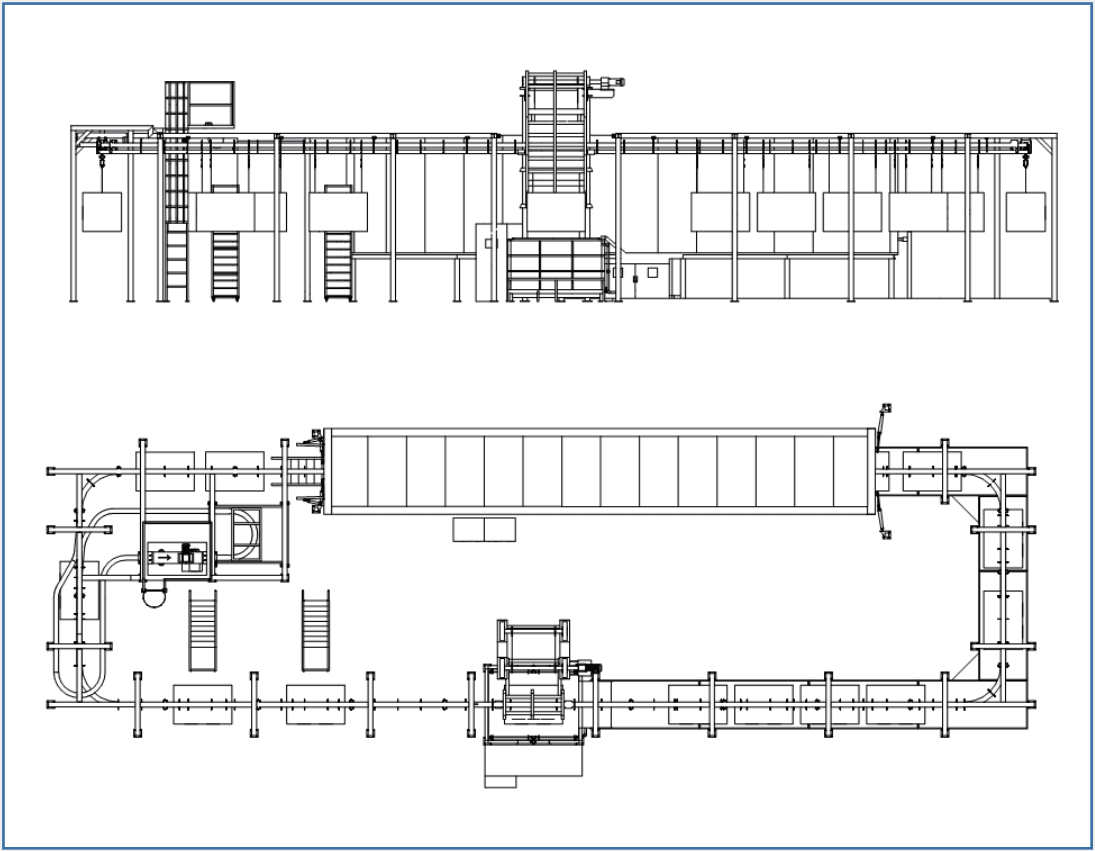

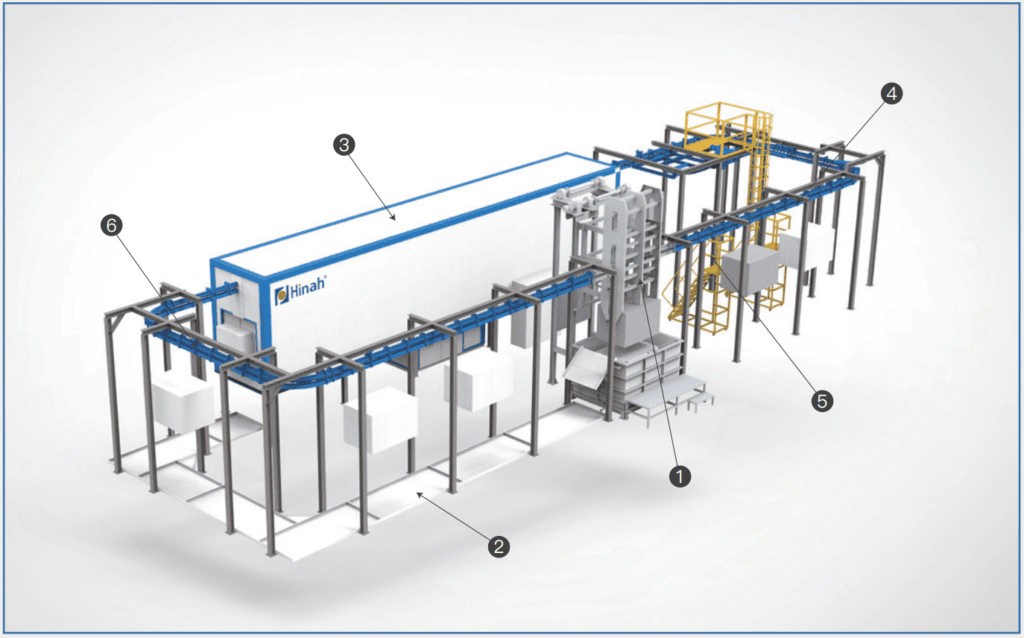

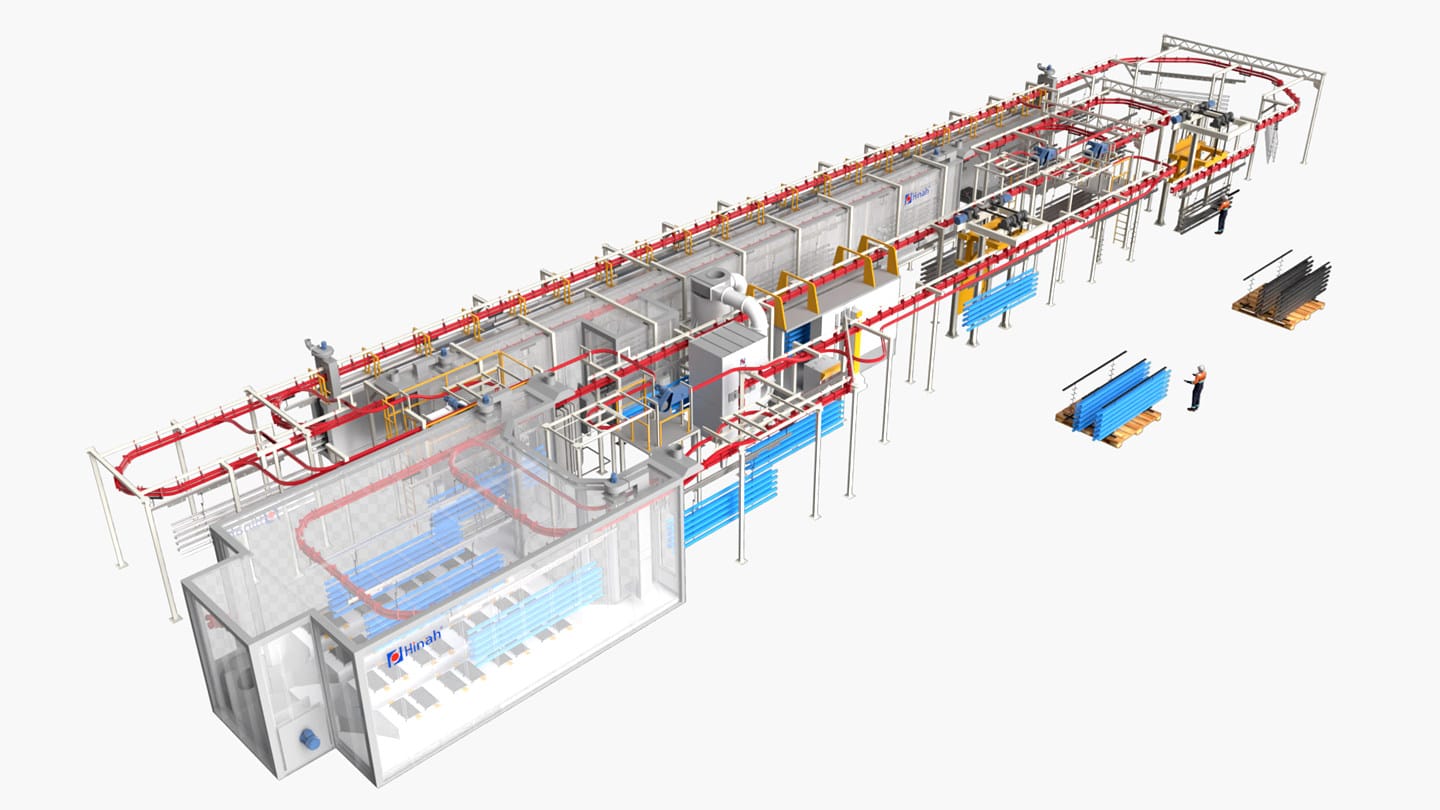

Case 2: Liquid Dipping Line

① Automatic varnishing system

② Paint receiving tray

③ Curing oven system

④ Unloading ladder

⑤ Loading ladder

⑥ Conveyor chain

High level of automation, reliable operation, and low maintenance costs.

High production efficiency with a precise control system ensuring consistent coating batch production and accurate thickness control.

With wide applicability, our coating lines can accommodate workpieces of various sizes and shapes.

Tailored to your needs

- Increase production efficiency.

- Flexibility and adaptability.

- Enhanced product quality.

- Reduced operating costs.

- Better matched intelligence and automation.

Need a design plan, now?

How it Works

Professional Powder Coating Line Installation Services

We offer professional powder coating line installation services and are committed to meeting the needs of our customers.

Our installation team consists of nine experienced teams, with each team member having at least five years of installation experience. This enables us to respond quickly to customer requests and successfully complete installation tasks within the specified timeframe.

Efficient installation process

We understand that time is of the essence for our customers, so we aim to ensure that installations are carried out efficiently.

With a wealth of experience and professional technical support, we strive to meet our customers’ expectations and provide a smooth installation experience to ensure that your line is up and running as soon as possible.

Timely quotes and lead times

At Hanna, we promise not to waste your time. Firstly, we will identify your specific needs and based on that we will design the best solution for you.

Once the solution is confirmed, you will receive a quotation for the powder coating equipment within usually three working days.

Prioritizing your order

After placing your order, your powder coating equipment becomes our top priority.

Regardless of the project requirements, Hinah Technologies will work with you quickly and at a reasonable price. We invite you to contact us to discuss your design options to better meet your needs.

Need a design plan, now?

Free Design & Order Equipment Calculation

In Order To Provide You With The Best Solution, Please Tell Us The Following Information

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.