Automated powder coating line relies on powder coating conveyor systems to improve overall production efficiency and stability, ensure high-quality execution of the coating process, and significantly reduce manual operation costs. With the continuous advancement of technology, these conveyor systems can not only efficiently handle large-scale production, but also achieve higher precision and consistency, providing flexible production solutions for the manufacturing industry and meeting the modern market’s demand for efficient and environmentally friendly coating processes. This article will give a detailed introduction to the powder coating conveyor system to help better understand its important role and advantages in automated coating lines.

I. What is a powder coating conveyor system?

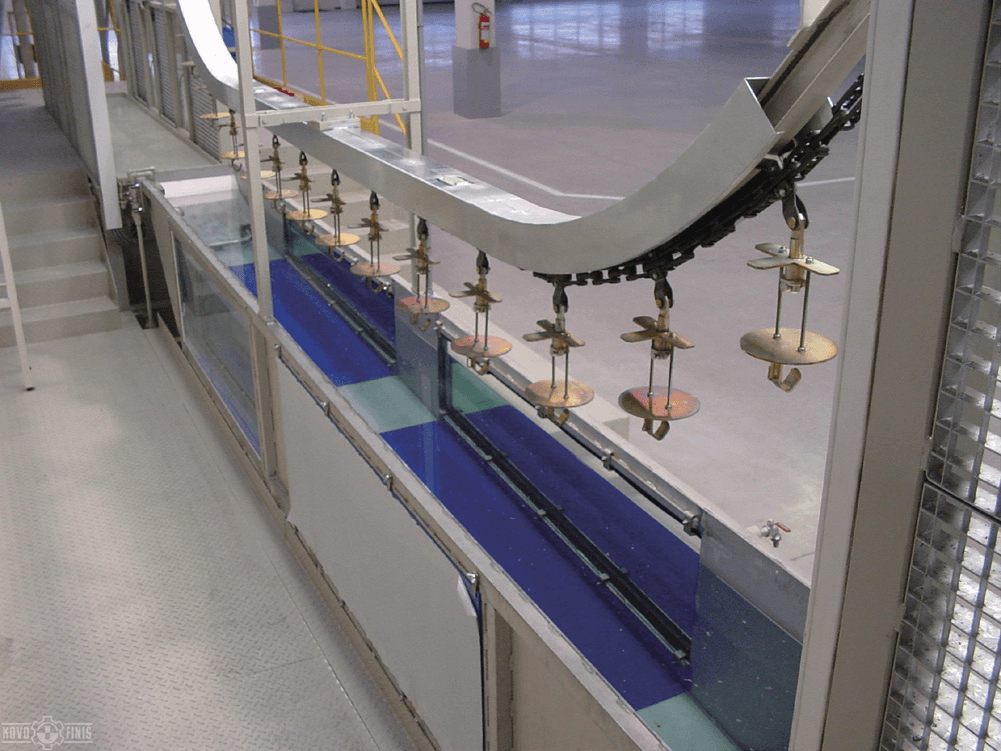

The powder coating conveyor system is a key component in an automated coating line, used to efficiently and stably transport the workpieces to be coated. The system is designed to improve the efficiency of the production line and the consistency of the product, while reducing manual intervention and operating costs. The powder coating conveyer system ensures uniform coating coverage and coating quality during the coating process through precise control and efficient material transfer.

II. What are the advantages?

1. Improve production efficiency

The powder coating conveyor system significantly reduces manual operations’ time and labor costs by automating the transportation of workpieces. The high-speed, continuous operation of the system greatly speeds up the production process. Traditional manual operations require frequent handling and processing of workpieces, while automated conveyor systems can efficiently transport workpieces from one workstation to the next process without interruption, greatly increasing production speed. In addition, the efficient operation of the system can meet the needs of mass production and ensure that the production line remains efficient and smooth.

2. Ensure coating uniformity and product quality

The powder coating conveyor system can precisely control the moving speed and position of the workpiece to ensure the consistency of the coating process. This precise control allows the powder coating to evenly cover each workpiece, eliminating uneven coating thickness, skips, or overcoats. Because coating uniformity is critical to final product quality, powder coating conveyor systems help ensure that every product meets the same coating standards through stable conveyor and operation processes, thereby improving product quality and consistency.

3. Improve factory space utilization and reduce labor costs

Automated powder coating conveyor systems can optimize factory layout and reduce the space required for traditional manual operations. In automated conveyor systems, workpieces can be transported efficiently vertically or horizontally, reducing the space required to transport workpieces within the factory. This not only improves space utilization, but also reduces the intensity of manual handling, further reducing labor costs. In addition, automated systems reduce the need for manual operations, allowing factories to devote more resources to other efficient production links.

4. Improve operational safety

Because the powder coating conveyor system operates under automated control, manual intervention is reduced, thereby reducing potential risks in the operation. Workers no longer need to be exposed to high-temperature curing ovens for long periods or perform heavy lifting work within the painting area. Modern systems are usually equipped with intelligent monitoring and fault detection functions, which can detect and handle faults in time to ensure the stable operation of the system. By reducing manual intervention and potential operational risks, powder coating conveyor systems greatly improve operational safety, help reduce the incidence of workplace injuries, and create a safer working environment.

III. Types of Powder Coating Conveyor Systems

There are many types of powder coating conveyor systems, each of which is adapted to different production needs and working environments.

1. Automated Conveyor System

Automated conveyor systems are systems that use automation technology to achieve material transportation. They are usually combined with sensors, drive devices, and control systems, and can intelligently adjust the transportation speed and path to achieve automatic transportation of workpieces.

2. Power and Free Conveyor System

A powder and free conveyor system is a system that can accumulate workpieces on the conveyor chain without affecting the subsequent transportation of workpieces. This system is usually used in situations where workpieces need to be accumulated, waited for, or distributed.

3. Manual Conveyor System

Manual conveyor systems rely on manual operation to transport workpieces. Usually, this system is simpler, and workers move workpieces by pushing, pulling, or manipulating the conveyor.

4. Comparison of different types of systems

Type | Advantages | Disadvantages | Applications |

Automated Conveyor System | High efficiency, intelligence, reduced manual intervention, good consistency | High initial investment, complex maintenance | Industries with large-scale production and high requirements for coating quality, such as automobile manufacturing, home appliance production, etc. |

Power and Free Conveyor System | Strong flexibility, reduced interruptions, optimized production process | Large space occupation, complex maintenance | Production lines that require accumulation and waiting, such as home appliances, electronic parts production, etc. |

Manual Conveyor System | Low cost, high flexibility, simple installation | High labor intensity, low efficiency, poor production consistency | Small-scale production, low-budget projects or customized production that requires high flexibility, such as small parts coating |

IV. How to choose the right powder coating conveyor system

Choosing the right powder coating conveyor system is crucial to improving production efficiency, ensuring coating quality, and optimizing costs.

1. Production scale

- Large-scale production: If the production volume is large and efficient and continuous operation is required, it is recommended to choose an automatic conveyor system, which can greatly improve efficiency and consistency.

- Small-scale production: If the production volume is small or the customization requirements are high, a manual conveyor system may be more suitable because it is more flexible and has lower costs.

2. Workpiece type and size

- Heavy or large workpieces: It is suitable to choose chain or roller conveyor systems, which can carry heavier loads and effectively transport large-sized workpieces.

- Small or light workpieces: The slide conveyor system is more suitable for lightweight and small workpieces, which are flexible and efficient.

3. Budget and cost-effectiveness

- Adequate budget: If the budget allows, choosing an automated conveyor system can save costs in the long run through high efficiency and reduced manual intervention.

- Limited budget: If the budget is low, a manual conveyor system can be selected, which has a small initial investment and is suitable for small-scale production.

4. Factory space

- Limited space: If the factory space is limited, the overhead conveyor system is a better choice because it can utilize the air space and save the ground area.

- Ample space: For larger factories, roller or chain conveyor systems can provide flexible ground transportation paths.

V. Maintenance and care of powder coating conveyor system

The powder coating conveyor system can extend the life of the equipment, reduce the failure rate, and improve production efficiency through regular maintenance.

1. Regular cleaning

Cleaning is the basis for maintaining the powder coating conveyor system, especially to prevent the accumulation of powder residues, which may cause the system to be blocked or run poorly. Regular cleaning of powder can not only improve the operating efficiency of the equipment but also prevent the powder from wearing the system components. It is recommended to perform a comprehensive cleaning once a week, using compressed air or a vacuum cleaner to remove the powder to ensure that the inside of the system is kept clean.

2. Check and lubricate the transmission components

The transmission components in the powder coating conveyor system, such as chains, rollers, and slides, are key components for the smooth operation of the system. Regularly checking the wear of these components to ensure that there is no damage or looseness is a prerequisite for ensuring the normal operation of the system. At the same time, regularly adding lubricating oil or grease to the transmission components can reduce friction, reduce wear, extend the service life of the equipment, and ensure its smooth operation.

3. Check the electrical system

With the development of automation technology, powder coating conveyor systems are usually equipped with electrical control systems and sensors to ensure precise control during the production process. It is very important to regularly check the connection of the electrical system and the working status of the sensors. Ensure that the cable connection is secure to avoid loosening or breaking. The sensor should also be calibrated regularly to ensure the accuracy and stability of the system operation.

4. Adjust tension and alignment

The chains, belts, or rollers of the conveyor system need to maintain appropriate tension and precise alignment to ensure smooth transportation of workpieces. Check the tension of the system regularly to ensure that the chain or belt is not loose. If an imbalance or offset is found, it needs to be adjusted in time. Improper alignment will not only lead to reduced system efficiency, but also may cause additional wear on components, so it is crucial to keep the conveyor system properly aligned.

5. Check safety devices

Safety is an important consideration in any production equipment, and powder coating conveyor systems are no exception. The system should be equipped with protective facilities such as emergency stop buttons and safety railings. Check the working condition of these safety devices regularly to ensure that they can play a role in time when abnormalities occur to ensure the safety of operators.

VI. Conclusion

The powder coating conveying system is an indispensable part of the modern coating process. It not only improves production efficiency but also ensures the uniformity of the coating and product quality. Selecting the right conveying system, reasonable maintenance measures, and optimizing the system operation are the keys to ensuring efficient and stable operation of the production line. By correctly selecting the right type of conveying system, enterprises can maximize production capacity and reduce operating costs. In addition, regular cleaning, lubrication, inspection, and adjustment can not only extend the service life of the equipment but also reduce unexpected downtime and maintenance costs, thereby improving overall production efficiency.