In the powder coating process, the powder curing oven is a key equipment to ensure the quality of the coating. Choosing the right curing oven affects the coating effect and is directly related to production efficiency and cost. This article will briefly introduce the basic functions of powder curing ovens, different types of equipment, and how to ensure uniform coating curing. In addition, we will also explore the price range of powder coating ovens on the market to help you make an informed purchasing decision.

I. Basic functions of powder curing oven

The powder curing oven is a vital equipment in the coating process. It heats the coating to a specific temperature so that it melts and firmly bonds with the substrate. This process not only ensures the durability and beauty of the coating, but also improves production efficiency. The curing of powder coating is not only a technical requirement, but also the key to ensure the quality of each product. Without it, the coating effect cannot last.

The curing oven ensures that every coating is perfectly cured and uniform through precise temperature control. Moreover, it saves energy for the factory, increases production speed, and allows your products to be painted in a shorter time. It is not only energy-saving and environmentally friendly, but also makes work more efficient and smooth.

II. Different types of powder curing ovens

Choosing the right powder curing oven can greatly improve production efficiency. Each curing oven has its own unique advantages and is suitable for different production needs. Understanding these types can help you make the most appropriate choice.

1. Tunnel curing oven

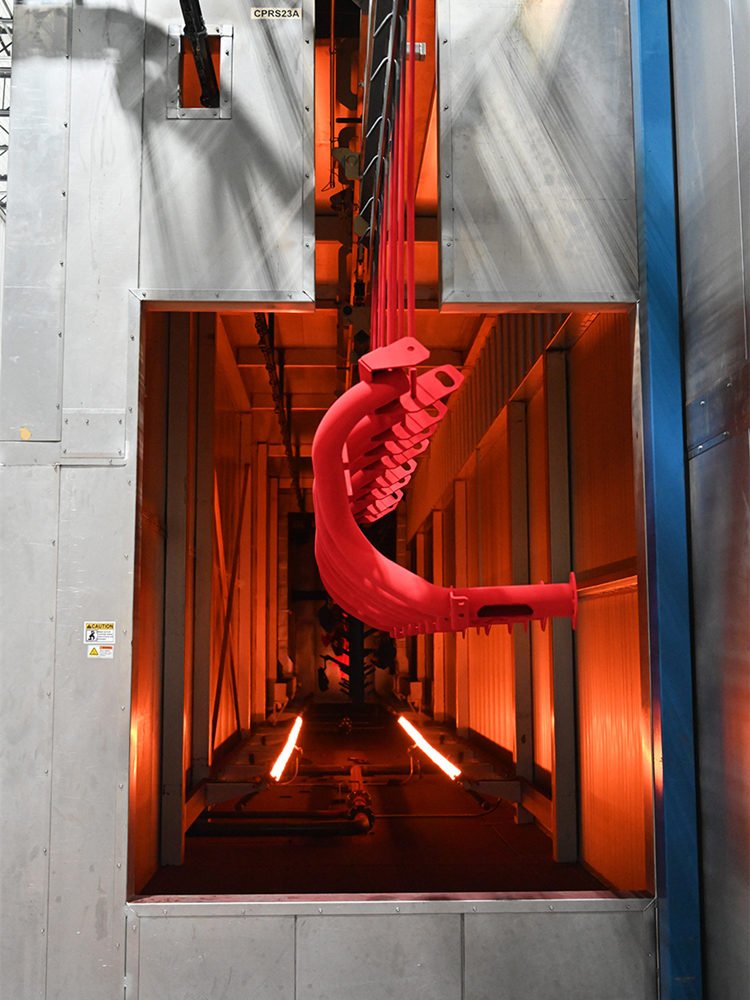

Tunnel curing oven is suitable for large-scale production. Its design allows the workpiece to pass through the heating area while constantly moving, achieving continuous production results. It is suitable for long-term, large-volume coating, with high efficiency and strong adaptability.

2. Box curing oven

Box curing oven is suitable for small-batch production or diversified production needs. Its design is flexible and can handle workpieces of various sizes. Although the production speed is slightly slower, for some special products, box curing ovens can provide more precise temperature control.

3. Bridge curing oven

The bridge curing oven combines the advantages of tunnel and box curing ovens and is suitable for production environments with limited space. Its heating area can be flexibly adjusted by a mobile device, which is very suitable for small to medium-sized production lines.

III. How to make the curing more uniform?

During the coating process, it is crucial to ensure that the coating is cured uniformly. A good powder curing oven can provide precise temperature control to avoid curing problems caused by uneven heat distribution. Here are a few key factors to ensure uniform curing:

3.1 Temperature control system

An efficient powder curing oven needs to have a precise temperature control system to ensure uniform temperature distribution in the oven. If the temperature is too high or too low, the coating may sag, bubble or fall off. The ideal curing oven will be equipped with multi-point temperature sensors to adjust and maintain a constant temperature in real time.

3.2 Air circulation design

Good air circulation design is another key to ensure uniform curing. The fan and air flow system in the powder curing oven should be able to achieve stable airflow throughout the oven cavity to avoid large temperature differences. Uniform airflow ensures that the coating is heated evenly, thereby achieving the best curing effect.

3.3 Reasonable curing time and temperature settings

Different types of coatings have different requirements for curing time and temperature. The powder curing oven needs to be able to adjust the heating time and temperature according to the specific requirements of the powder coating. Generally speaking, the temperature should be controlled between 160℃ and 200℃ and maintained for a certain period of time to ensure that the coating is fully and evenly cured.

IV. How much usually does a powder coating oven cost?

The price of a powder coating oven varies greatly, depending on multiple factors, such as the type of oven, size, functional configuration, brand, and customization requirements. Generally speaking, the price range can range from a few thousand dollars to tens of thousands of dollars.

1. Small ovens

For factories with small batches or limited space, the more affordable small box-type powder curing ovens are usually between $3,000 and $8,000. They are suitable for handling smaller workpieces and are relatively energy-efficient, but have lower production efficiency.

2. Medium ovens

Medium-sized powder curing ovens, such as bridge or medium-sized box curing ovens, are suitable for medium-sized production lines and generally cost between $8,000 and $20,000. These ovens usually have higher temperature control accuracy and better air circulation systems, are highly adaptable, and can handle workpieces of different specifications.

3. Large ovens

For large-scale production companies, tunnel-type powder curing ovens are the most common choice, and the price is usually between $20,000 and $50,000, or even higher. They are suitable for continuous production and can greatly improve production efficiency. Such ovens are usually equipped with efficient temperature control systems and air flow designs to ensure the uniformity and quality of the coating.

If your production has special requirements (such as custom sizes, specific temperature control requirements or higher energy efficiency), customized powder curing ovens may add additional costs. Such equipment usually needs to be designed according to specific requirements and the price may be higher.