Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Home » Products » Automatic Powder Coating Line » Automatic Aluminium Powder Coating Equipment Supplier

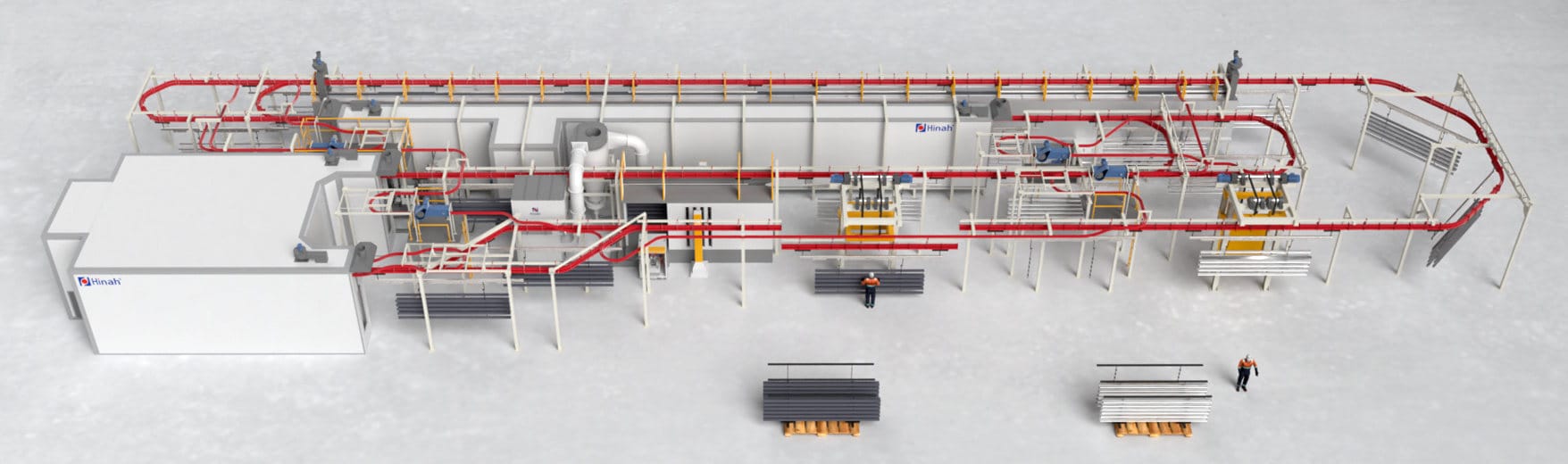

Automatic Aluminium Powder Coating Equipment Supplier

Flexible and efficient coating system.

Process Flow: Loading– Pre-Treatment –Drying–Automatic Powder Coating –Curing –Cooling –Unloading

1. Workpiece Name: Aluminium Profile

2. Maximum Size: L7000*W500*H1700 (Mm)

3. Area Size: 89m*15m

4. Heating Method: Natural Gas

5. Conveying Specifications: Qxg250 Type

6. Conveying Length: 500 Meters

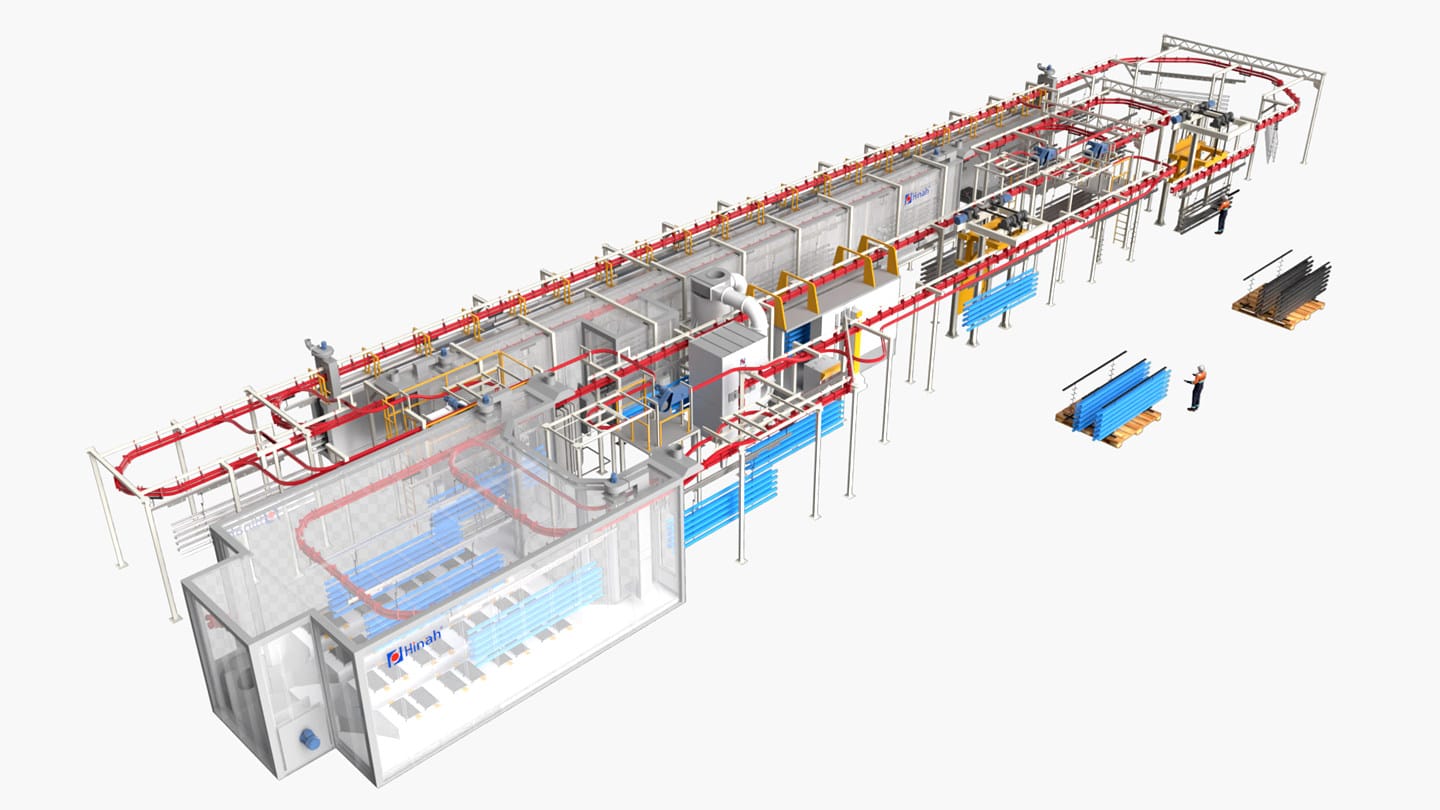

Design and features

Adjusted at a later stage

Design of accumulation and release conveying system: In view of the long and thin characteristics of user workpieces, we designed an accumulation and release conveying system to avoid the rotation of long workpieces during the conveying process. This design solves the problem of too large floor space, so that the entire production line can choose to stop accumulation or move at each process end according to the automatic control requirements, thereby saving equipment space and reducing furnace energy consumption.

Pre-treatment process optimization: Taking advantage of the characteristics of the accumulation and release line, we adopt the method of stopping spraying, so that two tank liquids can be used for spraying processing in one station shed. This design effectively saves equipment costs and floor space.

Spraying system technology improvement: The spraying system adopts PP powder spray room and large cyclone magic color change structure, and automatically identifies the workpiece position through grating detection to realize automatic control of spray gun start and stop. This technology reduces the blind spraying state after startup, improves equipment efficiency and paint utilization.

Human-machine interface control design: Each operation point of the production line is equipped with a human-machine interface console, which realizes unified and coordinated control of different workstations and ensures good operation results.

Improved overall benefits: Through the above design and optimization, not only the production efficiency is improved, but also the equipment space and energy consumption are significantly reduced, and the overall benefits are significantly improved.

- All Types Of Equipment For Powder Coating Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 24 Months Warranty And Lifetime Service

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Contact Us -- Free Design & Order Equipment Calculation

Order Equipment Calculation

In Order To Provide You With The Best Solution, Please Tell Us The Following Information

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.