Home » Products » Automatic Powder Coating Line » Automatic Powder Coating Line for Gas tanks

Automatic Powder Coating Line for Gas tanks

Flexible and efficient coating system.

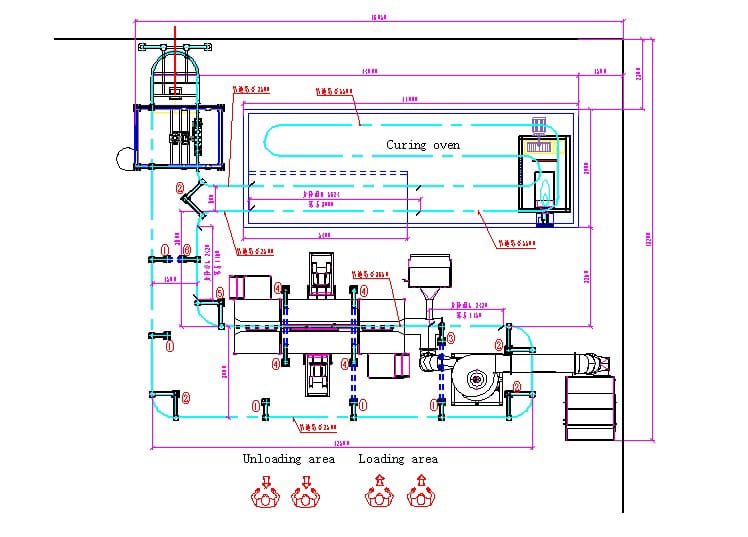

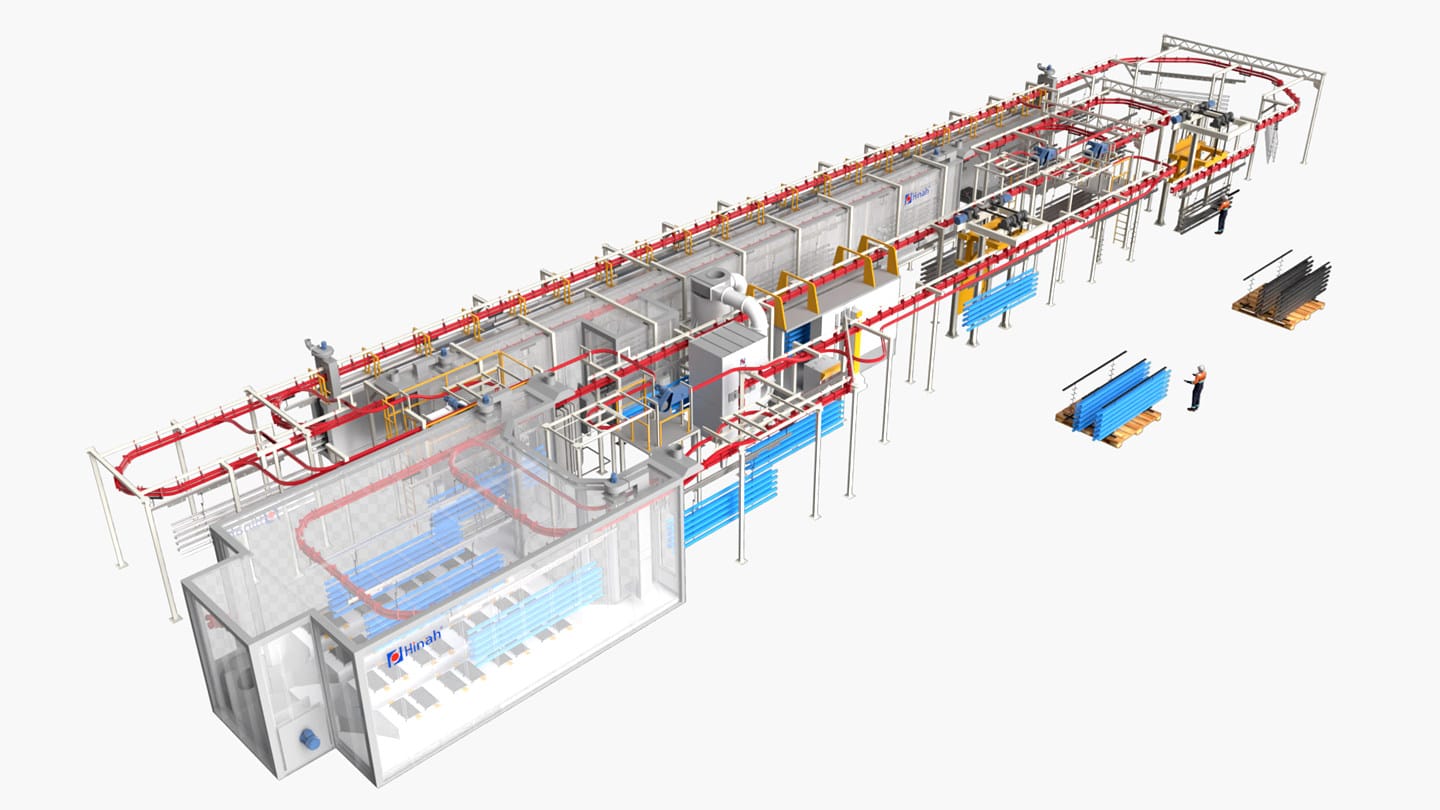

Process Flow: Loading– Pre-Treatment –Drying–Automatic Powder Coating –Curing –Cooling –Unloading

1. Workpiece Name: Gas Tank

2. Maximum Size: L500*W500*H1200 (Mm)

3. Area Size: 46m*50m

4. Heating Method: Natural Gas

5. Conveying Specifications: Qxg250 Type

6. Conveying Length: 160 Meters

Design and features

Adjusted at a later stage

1. This line is a fully automatic powder spraying line for gas pipes, suitable for a layout with an area close to a square.

2. This line uses the QXG250 standard chain as the main body of the workpiece conveying system, which is low-cost, durable, and has a low failure rate.

3. The entire line layout is simple, and the upper and lower parts areas are on one side, which is convenient for loading and unloading.

4. The spraying part adopts a large cyclone-type recovery powder mill, which has high online spraying efficiency, simple and fast color change, and high spraying efficiency, and is suitable for fast and efficient spraying.

5. The spray gun adopts a Debel spray gun, which has high powder loading efficiency, fast spraying speed, and good durability.

- All Types Of Equipment For Powder Coating Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 24 Months Warranty And Lifetime Service

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Contact Us -- Free Design & Order Equipment Calculation

Order Equipment Calculation

In Order To Provide You With The Best Solution, Please Tell Us The Following Information

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.