Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Powder Coating Conveyor System

Advanced technology, energy saving, high efficiency.

Conveyor systems play a critical role in the efficiency and productivity of powder coating operations, facilitating the movement of workpieces through various stages of the coating process.

Type1: Automated Conveyor

Advanced technology, energy saving, high efficiency.

• Fully Automated: Operates with minimal human intervention, controlled by motors and systems;

• Continuous Production: Ideal for high-volume, continuous production environments;

• High Efficiency: Reduces labor and errors, ensuring steady material flow;

• Fixed Path: Limited flexibility, as the path is predefined;

• Simple Operation: Easy to control with minimal manual input;

• International Brand, High Degree Of Safety;

• Suitable for large-scale, standardized production like automotive or metal coating.

Features

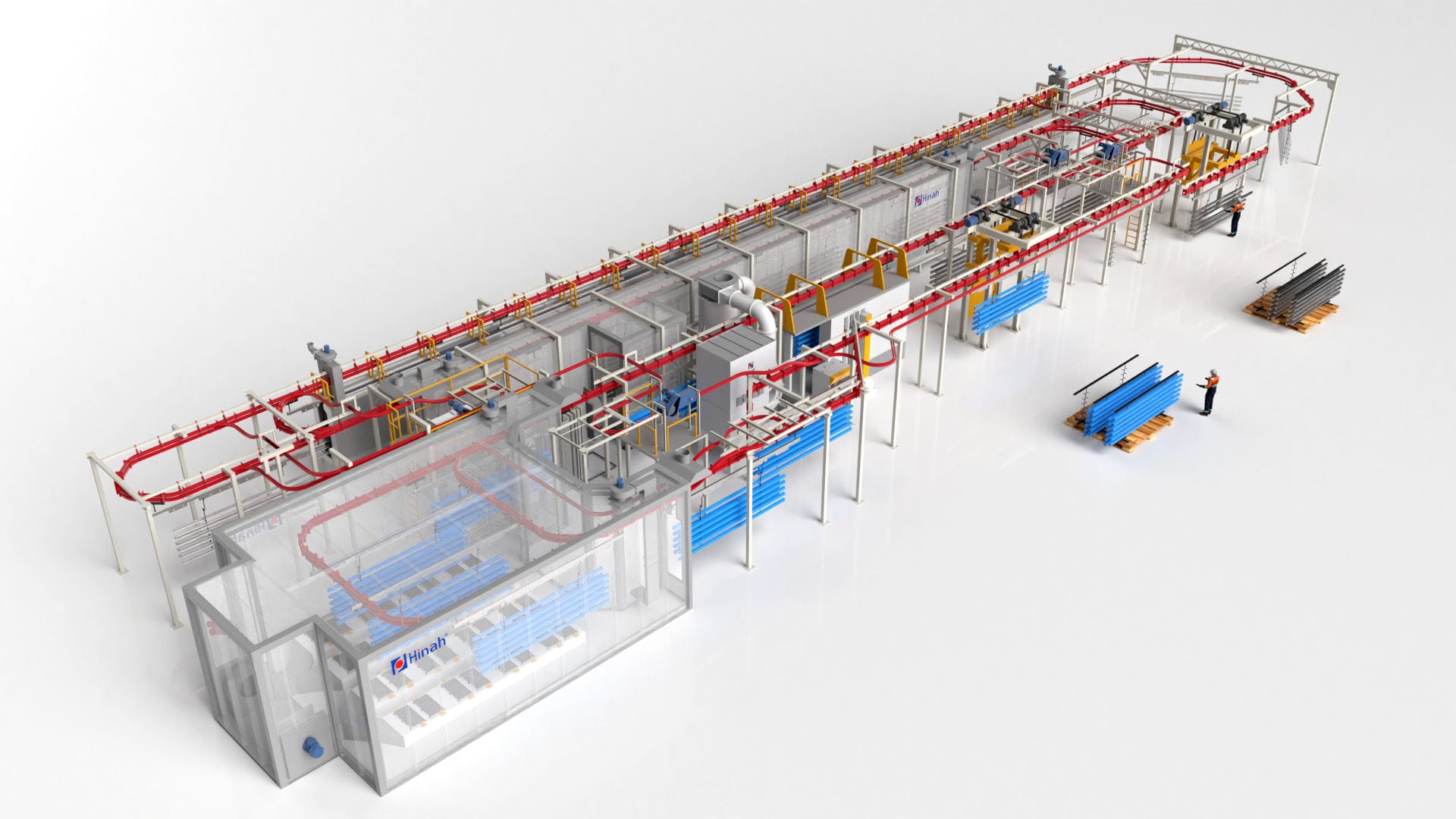

Powder Coating Line with Automatic Conveyor System

Automatic Conveyor System Powder Coating Line

- All Types Of Equipment For Powder Coating Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 12 Months Warranty And Lifetime Service

Automated Conveyor:

Our automated conveyor system is designed for seamless and continuous transportation of workpieces along the powder coating line. It features a motorized belt or roller conveyor that moves at a predetermined speed, carrying workpieces from one station to the next with precision and reliability. The automated conveyor system is ideal for high-volume production environments, offering consistent throughput and minimizing manual handling.

Key Features of Automated Conveyor:

Smooth and continuous movement of workpieces.

Precise control over speed and direction.

Compatible with various types of workpieces and coating processes.

Reduces labor requirements and improves efficiency.

Type2: Power and Free Conveyor

Advanced technology, energy saving, high efficiency.

- Flexible Movement: Combines motorized movement with the ability to detach and move independently;

- High Flexibility: Can reroute products, stop, or pause at different workstations;

- Adaptability: Perfect for complex, multi-path production lines;

- Energy-Efficient: Uses energy only when moving, reducing waste;

- Independent Operation: Products can run independently, optimizing workflow;

- Ideal for complex processes or small to medium batch production, like automotive or electronics coating.

Features

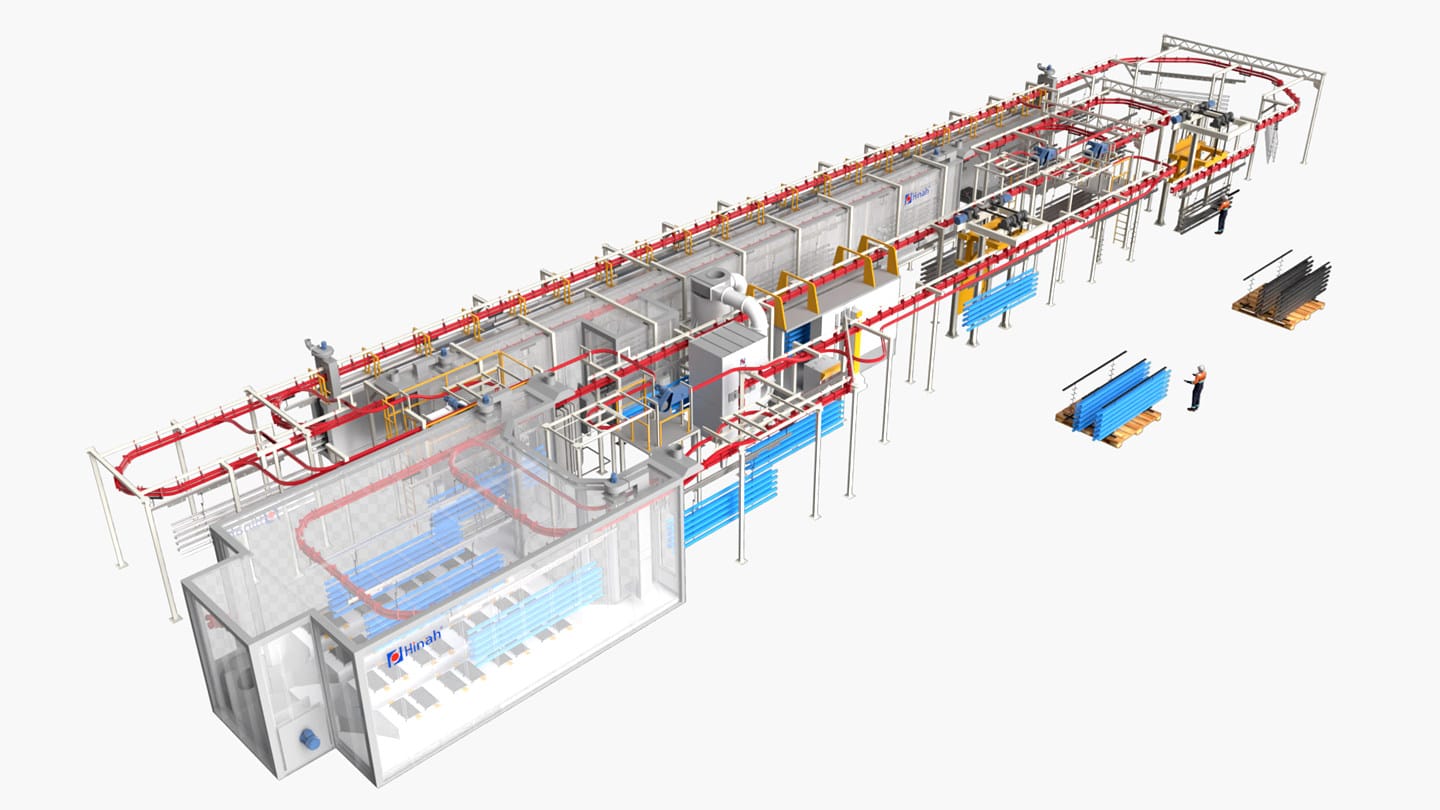

Automatic Powder Coating Line with Power and Free Conveyor System

Free Conveyor System Aluminum Profile Automatic Electrostatic Powder Coating Line

- All Types Of Equipment For Powder Coating Lines

- Any Size According To Customer's Requirements

- Production Within 45-90 Days

- Delivery And Professional Installation

- 12 Months Warranty And Lifetime Service

Power and Free Conveyor:

Our power and free conveyor system provides enhanced flexibility and versatility in powder coating operations. It consists of a track-mounted conveyor chain with powered trolleys (power chain) and a secondary load-bearing trolley (free trolley) that runs along an overhead track. This configuration allows for individual workpiece carriers to move independently along the track, enabling selective start and stop functionality and asynchronous operation. The power and free conveyor system is well-suited for complex coating processes with multiple stages or varying cycle times.

Key Features of Power and Free Conveyor:

Selective start and stop capability for precise control over workpiece movement.

Flexible routing options to accommodate different process requirements.

Allows for accumulation and staging of workpieces at various stations.

Maximizes production flexibility and throughput.

Proven

30 years of experience providing proven equipment

Lifetime Service

Maintenance is more important than repair

Maximum Efficiency

Production line capacity fully matches demand without wasting any resources

Contact Us -- Free Design & Order Equipment Calculation

Order Equipment Calculation

● Factory Dimensions (length, width, height)

● Work Piece Output (1 day = 8 hours, 1 month = 30 days)

● Material of the workpieces

● Dimensions of work piece

● Weight of the workpieces

● Color Change Demand (Frequency)

In Order To Provide You With The Best Solution, Please Tell Us The Information

We closely communicate with clients to understand their needs and provide tailored solutions. Once the solution fits their requirements, we customize the production of the powder coating line to help them adapt to their specific production environment and coating needs.

/CONTACT US

Want to Discuss Your Upcoming Product Line?

Hinah coating will help you get things done.

Email us

Tel (Whatsapp/Wechat)

+86-186 3213 8668

Learn How We Helped 1000+ Customers Gain Success.